Firing

After the drying step in the dryer machine, is the firing step in the brick kiln. At this point, the dried bricks must be placed at temperatures above 900 degrees Celsius in order to obtain the required strength and durability. When clay bricks are heated to very high temperatures, a chemical reaction is created in the clay, making the bricks permanently hard, durable, and resistant to weathering and moisture corrosion.

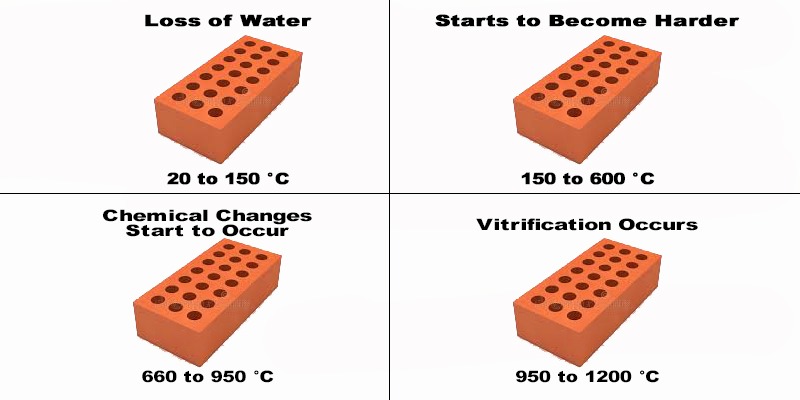

The variations of clay at different temperatures are shown in the following figure.

If firing stops at 600 degrees Celsius, the bricks will not be used for building purposes. Because the changes are not stabilized and are worn out by the wind and rain. When the temperature goes above 900 degrees, vitrification occurs in brick material. This means that some of the material, become like glass, melts and helps to cling to all the elements in the clay. After this step, the brick becomes its hardest and most durable state and is ideal for construction. The final quality of the brick depends on the amount of glazing that occurs.

Types of Brick Kiln (Firing)

There are two types of the kiln for firing brick:

The Hoffman kiln technology is too old with its inexpensive installation cost and high energy consumption. They are made in Iran and some other countries despite their high energy consumption.

The best method in firing bricks is done in tunnel kilns. They were popular since the 60s and 70s. As well as their high quality and low energy consumption they have the advantages of attaching loading and unloading machinery.K