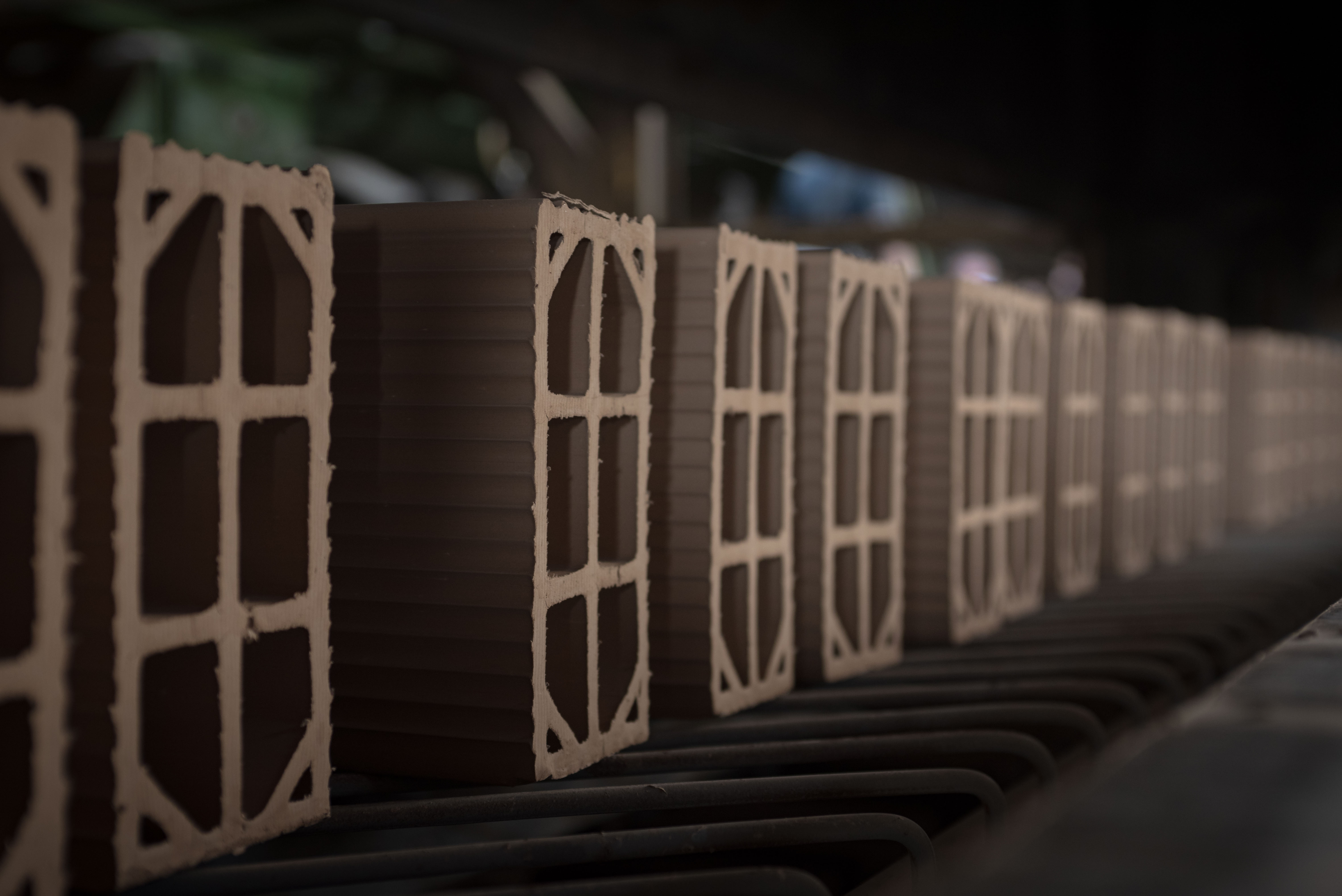

Higher numbers indicate a superior dryer.

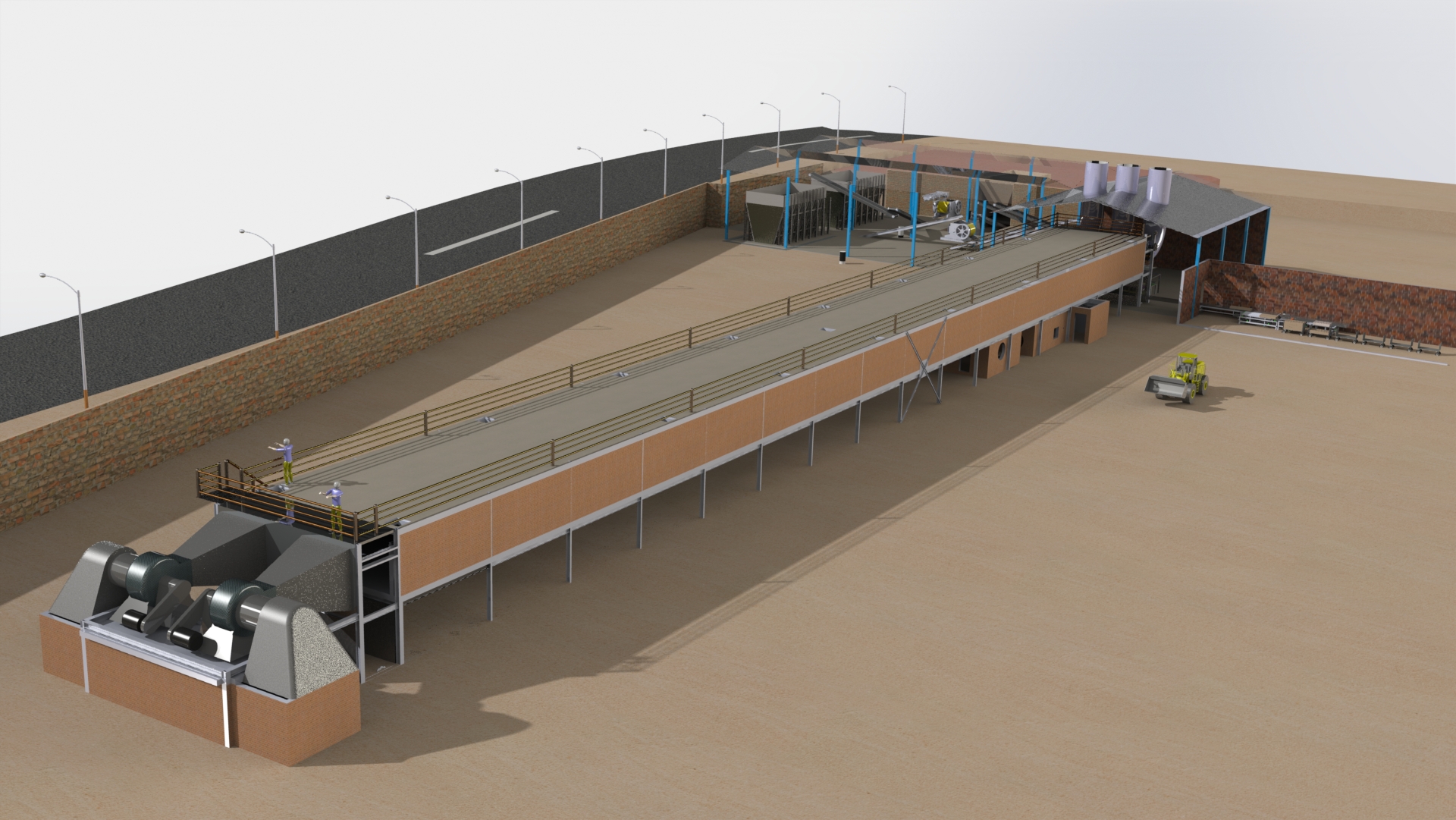

Total cost: The fixed cost considered for constructing the dryer from start to finish. Lower total cost means a higher score in the chart.

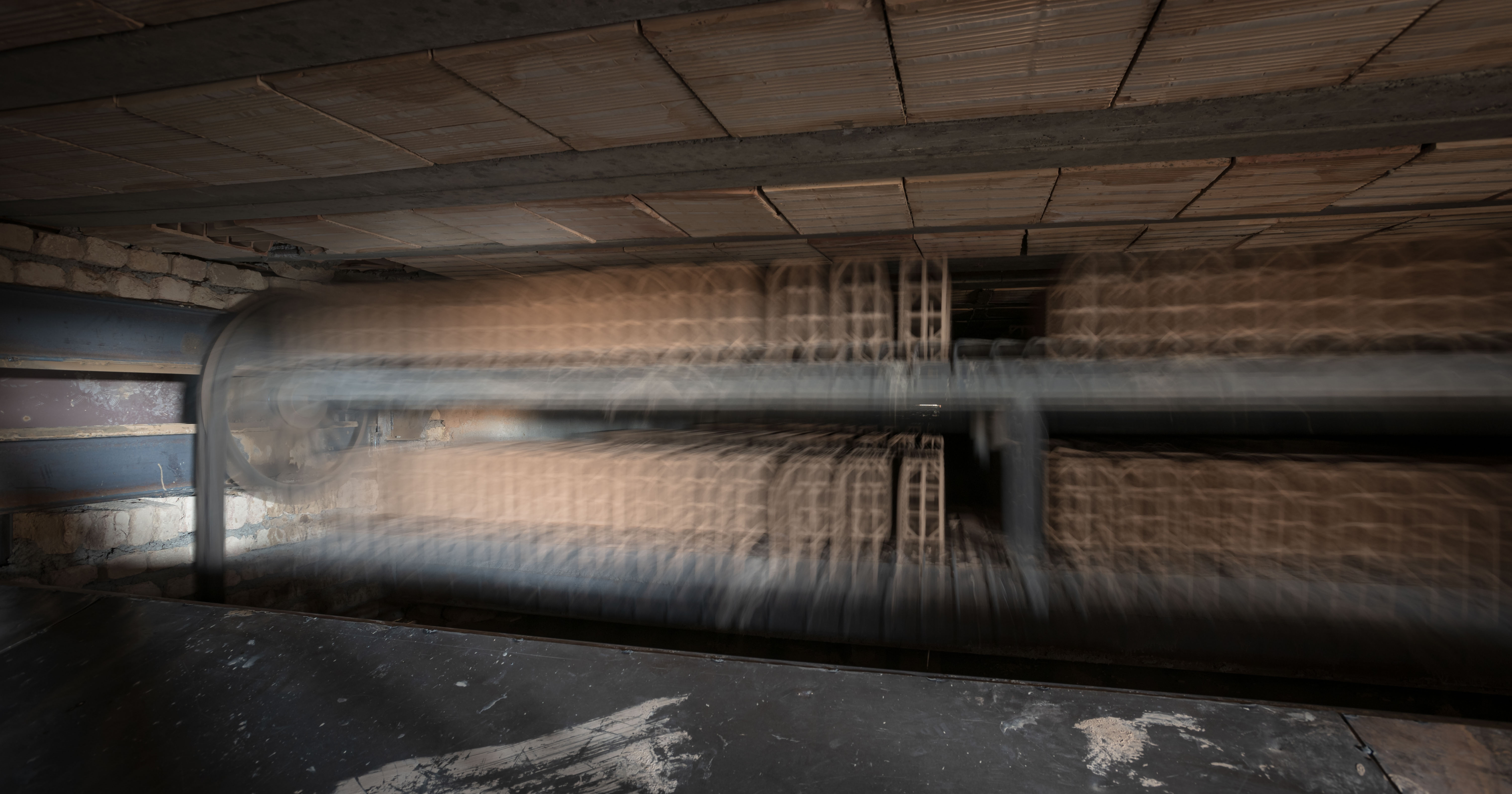

Lower energy consumption indicates a higher score.

Shorter drying time has a higher score.

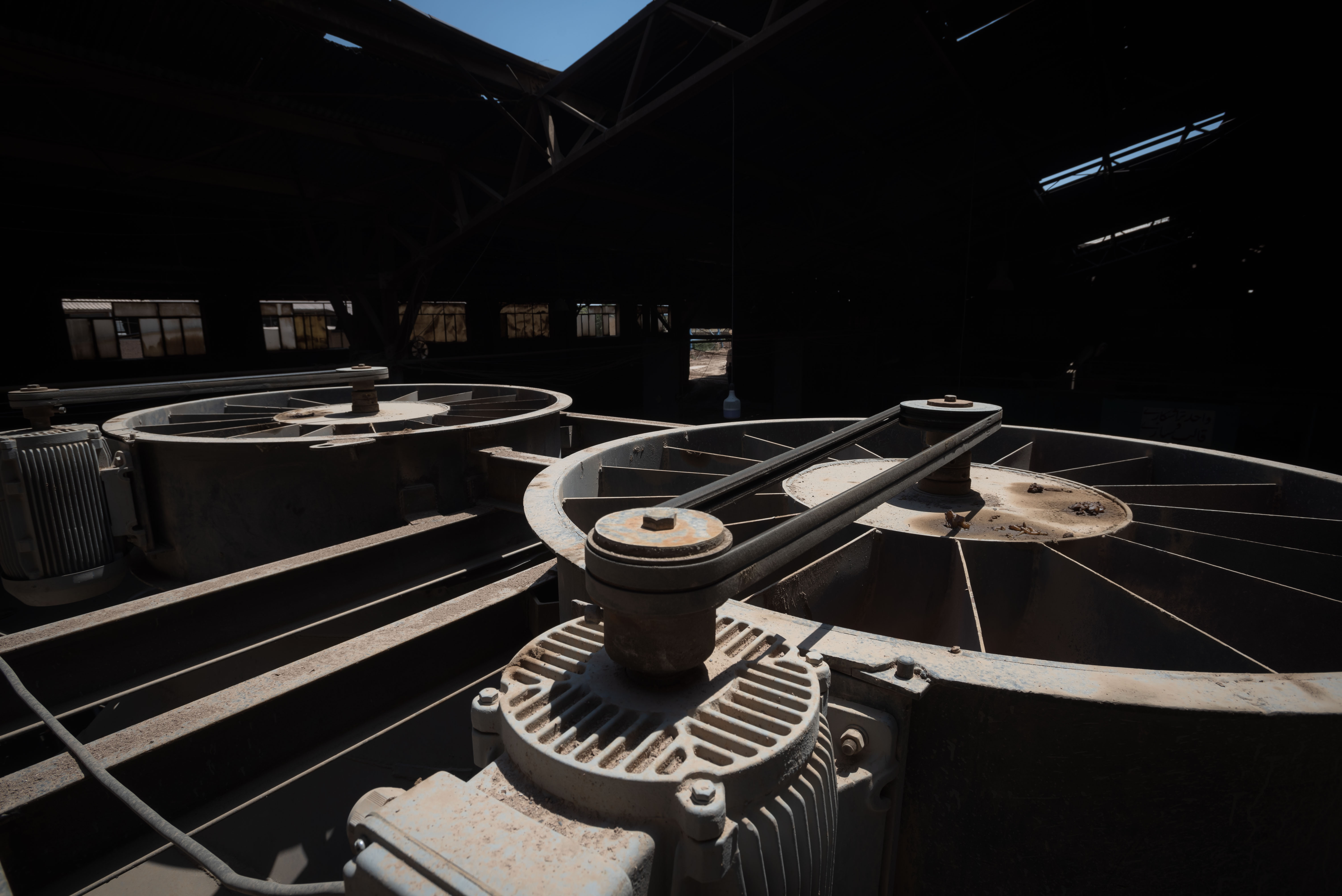

Lower maintenance and supply costs have a higher score.

Lower operating costs mean a higher score.