شرکت برنا گستر پارسی - سازنده ماشین آلات تولید آجر

Turnkeysolution

Turnkey solution:

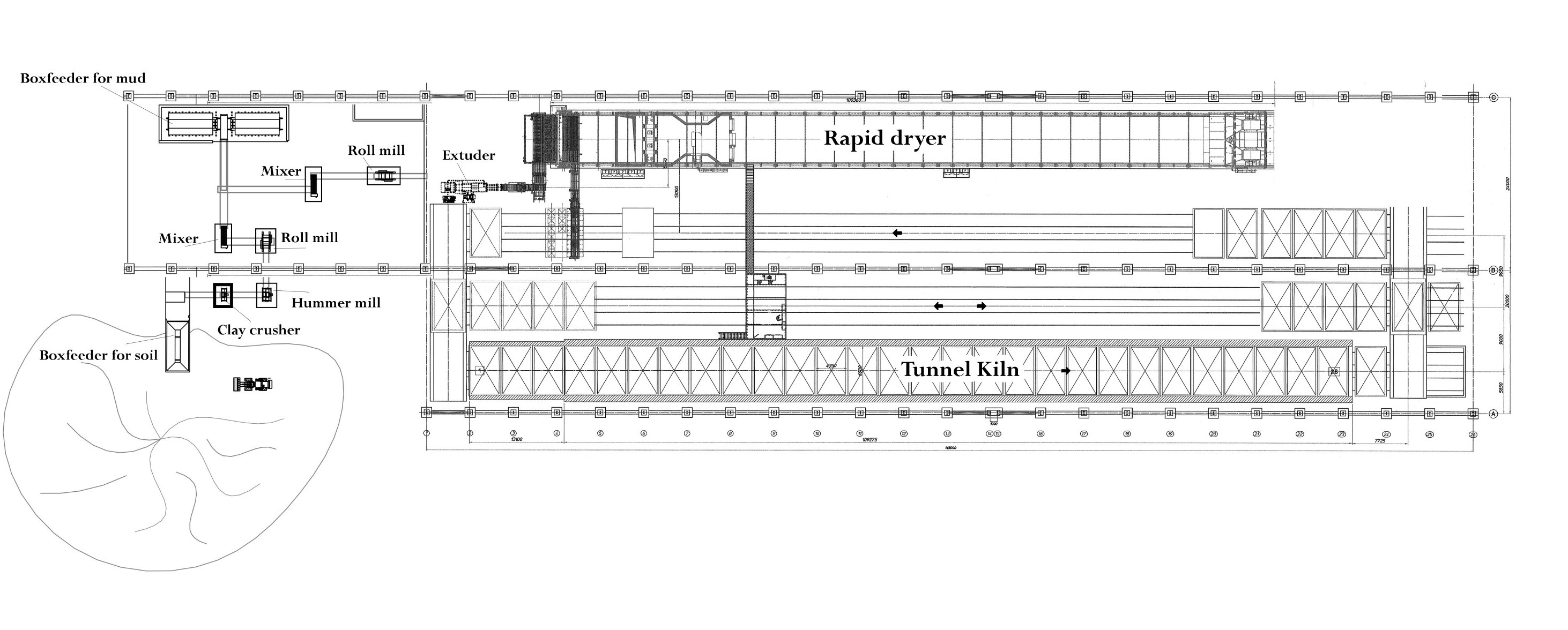

The brick complete production line in this factory uses advanced machineries and automated upgraded systems to produce high-quality bricks. The production phases include selecting and preparing raw materials, forming & shaping, drying the bricks, and finally baking them in industrial furnaces. Each phase is carefully controlled to ensure the final product meets the required standards. This process is continuously improved to enhance quality while decreasing energy consumption and reducing production time. The produced bricks are then prepared for use in construction projects, especially for facades and walls.

Turnkeysolution

Baking bricks in industrial furnaces

The bricks are fired in modern furnaces to have more strength & durability and having excellent amazing colors.

Brick Drying

The bricks are carefully dried to reduce cracking and increase durability.

Raw Material Preparation

Raw materials are carefully selected and prepared to ensure the final quality of the bricks.

Frequently Asked Questions

How raw materials are selected for brick production?

Raw materials such as clay and sand are carefully selected from reliable sources and tested to ensure high quality of the bricks.

How do bricks dry?

Bricks are dried using advanced industrial dryers or natural methods to increase their durability.

Is the production line customizable?

Yes, the production line can be customized based on your project needs and the type of final product.