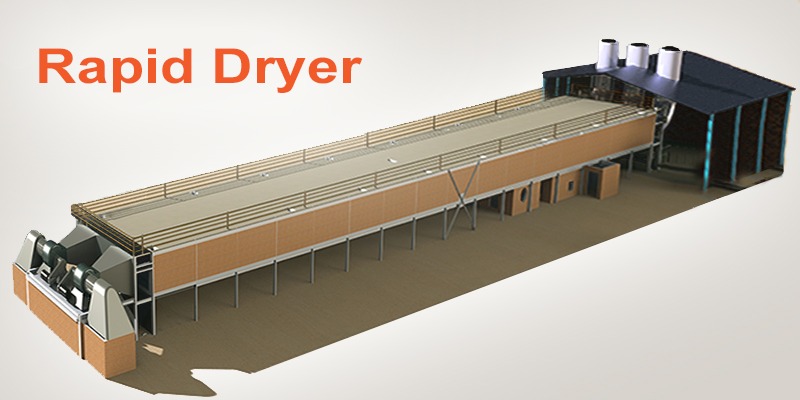

Brick Rapid Dryer (Rotary) (Tunnel)

The dryer is a very important part of the brick manufacturing process. The drying time and the quality of the brick are two important parameters in the drying process. There are different types of dryers and divided into two general categories: chamber and tunnel dryer. These dryers do not necessarily have an absolute advantage over each other. In general, tunnel dryers have more advantages over chambers, especially new tunnel dryers, which are highly controllable. In contrast, chamber dryers also have some advantages.

Borna Gostar Group is proud to have the technical know-how of the world’s most advanced brick dryers, that in these dryers, the mechanism is so that all sides of the bricks are equally exposed to heat and bellow. And all bricks go through the drying process equally, and this style of the dryer is not only useful for bricks but also for similar products like cement and gypsum.

Technical Specifications and Reforms of the Brick Rapid Dryer (Rotary)

- General design specifications

- Review and compare past technologies

- Design updates

- Design technologies

- Practical results

- Plans

General Design Specifications

The dryer is used in many industries, and is widely used in the building materials and food industries process of producing clay brick or, more generally, clay or shale based construction materials is as follows:

- Soil processing

- Forming

- Dryer

- Firing

Clay drying is one of the most important stages of brick production. This stage determines the quality, size, lightness and shape of the clay. That is to say, the type of dryer and its style ensures the ability to dry without cracking and make quality clay in different sizes and shapes.

Brick Rapid Dryer (Rotary) Designed and Developed by Borna Gostar Parsi Company, in addition to various advantages such as energy consumption and low cost and high efficiency, it has the potential to bring the clay brick industry into a new phase of diversification. Considering the fact that much larger sizes are produced, firmer and much lighter clay that in addition to the very low cost of the brick compared to existing building materials. And has excellent engineering parameters such as thermal and moisture insulation and increased construction speed.

Review and compare past technologies

Because the existing brick production and dryer industry was Reverse Engineering engineering without research, the available dryers are very expensive, costly, and inefficient. Soils in Iran are far better for producing bricks than existing soils licensed in Europe, And European technologies are mostly based on the experience and territory of their region.

The following table is a comparison of the designed and manufactured Rapid Dryers by Borna Gostar and conventional dryers in Iran.

[table id=9 /]

Design innovations

One of the most important innovations in Iran is the ability to recycle water used for brick production. As described, the drying mechanism is so unlike the past, the outlet air has a humidity above 90% and the water in the bricks is ventilated out of the three air outlets with a diameter of 2m. By adding cooling systems and with the very latest Co-generation technology in which there is low energy consumption in this system, it is easy to recycle more than 50% of water.

At worst, this water is returned to the brick production system, or in better condition, it can be collected as distilled water, which has a very high added value for producer.

Technologies

Borna Gostar Company has been achieved new technologies to make rotary rapid dryer. One of these technologies is the design and manufacture of the Vane Axial Fan with an efficiency of about 90%.

All Airfoils and static blades of this fan are engineered by company engineers without any reverse engineering, making it possible to provide high-efficiency dryers. To manufacture the blades of the fan, the highest level of die casting and component production and also the A380.1 alloy was used. The use of this alloy in the form of blades allows it to be produced with great precision without requiring CNC to form after casting.

Among the technologies used in this project:

- Movable shelf wheels

- Main Chain wheels of the movement

- Main moving chains

- Control and ventilation system.

Practical Results of Brick Rapid Dryer (Rotary)

After launching the project of Brick Rapid Dryer (Rotary), and after a certain amount of time, the following was quite noticeable on the corporate product line:

- Two and half years after the first project, line maintenance was at its lowest level.

- The current production capacity, proportional to the area’s soil, about twice the anticipated capacity.

- Very low power consumption than older models.

- Tangible increasing the quality in the final products And, after that, very high factory sales, in this few years of the market downturn

- Ability to produce very large (25 * 70 * 70) cm clay bricks, which older dryers are unable to produce.